|

The main components of Taibao air dryer are: 7. Drying rack: can be purchased by oneself or customized by the factory. Note: Users can send materials by express delivery or visit our company for trial drying. |

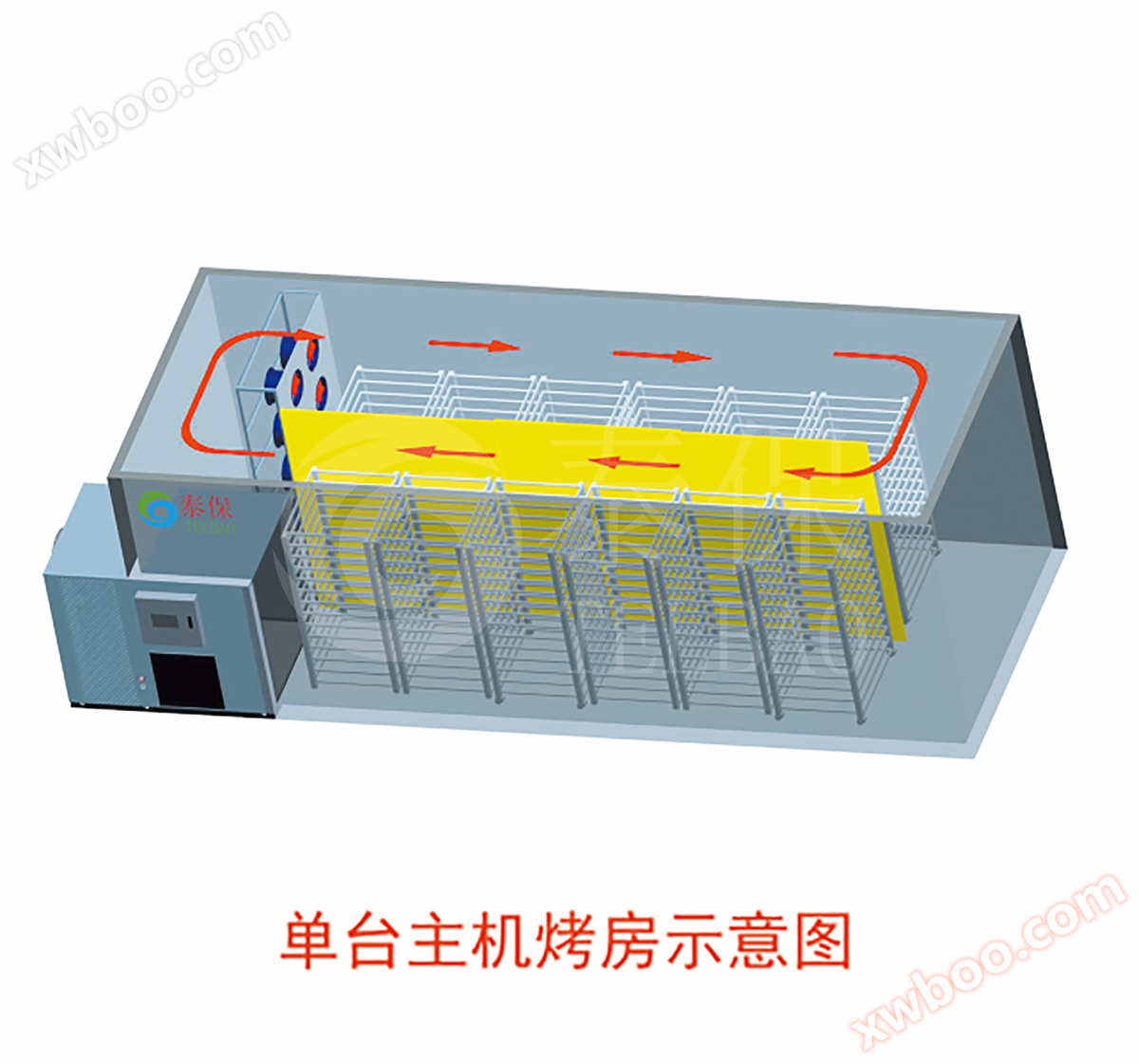

Multiple design schemes for reference, precise design:

Customer dryingcase

The main drying methods and principles of heat pump dryer

1. Prospect of heat pump dryer

The material drying process is a huge energy consuming process. According to statistics, in most developed countries, the energy consumed for drying accounts for 7% -15% of the total national energy consumption, while the thermal efficiency is only 25% -50%. Moreover, most drying processes, especially for heat sensitive materials such as food and biological materials, will have an impact on their color, nutrition, flavor, and organization. Heat pump drying technology has the advantages of low energy consumption, low environmental pollution, high drying quality, and wide applicability. Its excellent energy-saving effect has been proven by various experimental studies at home and abroad.

The operating cost of a heat pump dryer is only 30% of that of an electric heating dryer, 40% of that of a fuel fired dryer, and 60% of that of a coal-fired dryer, and the heat pump dryer does not consume any materials.2. Working principle of heat pump dryer

A heat pump is essentially a device for increasing heat. The high-temperature heat pump drying unit uses the reverse Carnot principle to extract heat from the surrounding environment and transfer it to the heated object (a higher temperature object). Its working principle is the same as that of a refrigeration machine, both working according to the reverse Carnot cycle, with the only difference being the operating temperature range.

The high-temperature heat pump drying and dehumidification unit mainly consists of four parts: a finned evaporator (external unit), a compressor, a finned condenser (internal unit), and an expansion valve. By continuously evaporating the working fluid (absorbing heat from the outdoor environment), compressing, condensing (releasing heat in the indoor drying room), throttling, and re evaporating, the heat from the external low-temperature environment is transferred to the drying room, and the refrigerant circulates in the system under the action of the compressor. It completes the process of gas pressure rise and temperature rise (up to 100 ℃) inside the compressor. It enters the internal unit and releases high-temperature heat to heat the air in the drying room. At the same time, it is cooled and converted into a liquid state. When it runs to the external unit, the liquid state quickly absorbs heat and evaporates back into gas, and the temperature can drop to -0 ℃~-10 ℃. At this time, the air around the heat absorber will continuously transfer heat to the refrigerant. The heating efficiency of a high-temperature heat pump drying unit is much higher than that of other heating equipment. It can be seen that using a high-temperature heat pump drying unit as a drying device can save energy and reduce the emissions of pollutants such as CO2, achieving energy-saving and emission reduction effects.

3. Application fields of heat pump dryer

◇ Medicine drying machine: Panax notoginseng drying machine, star anise drying machine, Morinda officinalis drying machine, Dendrobium officinalis drying machine, yam Huaishan drying machine, Ganoderma lucidum drying machine, sea cucumber hot drying machine, honeysuckle drying machine, siraitia grosvenorii drying machine, cinnamon drying machine, ginseng drying machine, ginger drying machine, Morinda officinalis drying machine, Maka drying machine, medlar drying machine, angelica sinensis drying machine, etc.

◇ Agricultural product dryer: Overlord flower dryer, rose dryer, chrysanthemum dryer, mushroom dryer, bamboo fungus dryer, sweet potato dryer, okra dryer, tobacco dryer, Tremella fuciformis dryer, fungus dryer, chili dryer, yellow flowered vegetable dryer, tea tree mushroom dryer, taro dryer, vegetable dryer, bamboo shoot dryer, cassava dryer, starch dryer, edible mushroom heat pump dryer, vegetable dryer, etc.

◇ Fruit dryer: longan dryer, litchi dryer, banana slice dryer, mango dryer, jujube dryer, jujube dryer, waxberry dryer, lemon dryer, grape dryer, jackfruit dryer, kiwi dryer, persimmon dryer, olive dryer, preserved fruit dryer, etc.

◇ Food dryer: sausage dryer, bacon dryer, dried fish dryer, sausage dryer, casing dryer, river flour dryer, Rice noodles dryer, sweet potato flour dryer, noodle dryer, noodle dryer, Rolls of dried bean milk creams dryer, etc.

◇ Seafood drying machine: sea fish drying machine, squid shred drying machine, shrimp drying machine, abalone drying machine, sea cucumber drying machine, squid drying machine, seahorse drying machine, Yaozhu drying machine, etc.

Tea drying machines: Pu erh tea drying machine, black tea drying machine, Da Hong Pao drying machine, Jin Jun Mei drying machine, Tie Guan Yin drying machine, green tea drying machine, Mao Jian drying machine, etc.

◇ Buddha Incense Drying Machine: Buddha Incense Drying Machine, Pan Incense Drying Machine, Thread Incense Drying Machine, Bamboo Stick Incense Drying Machine, Stick Incense Drying Machine, Craft Incense Drying Machine, Mosquito Repellent Incense Drying Machine, etc.

◇ Wood Drying Machine: Redwood Drying Machine, Redwood Furniture Drying Machine, Purple Sandalwood Drying Machine, Yellow Pear Wood Drying Machine, Black Sour Branch Drying Machine, Red Sour Branch Drying Machine, Ebony Drying Machine, Striped Ebony Drying Machine, Chicken Wing Wood Drying Machine, Redwood Help Finished Product Drying Machine, Redwood Furniture Paint Drying Room, Wood Floor Drying Machine, Wood Product Drying Machine, Bamboo Product Drying Machine, Bamboo Stick Drying Machine, Bamboo Glue Board Drying Machine, Bamboo Floor Drying Machine, Single Board Drying Machine, Eucalyptus Rotary Cutting Board Drying Machine, Building Template Drying Machine, etc.

Industrial product dryer: printing dryer, leather dryer, fabric dryer, gypsum dryer, plastic dryer, electroplating dryer, handicraft dryer, fireworks dryer, paper dryer, rubber dryer, etc.

◇ Production line dryer (tunnel dryer, belt assembly line dryer): rubber glove dryer, noodle tunnel dryer, straight Rice noodles dryer, gypsum block tunnel dryer, leather tunnel dryer, etc.

4. Characteristics of heat pump dryer

Easy to install: Easy to install and dismantle, occupies a small area, and can be installed indoors or outdoors.

Efficient and environmentally friendly: With only a small amount of electricity consumption, it can absorb a large amount of heat in the air, with a power consumption of only 1/3-1/4 of electric heating; Compared with coal, oil, gas, and water heaters, it can save about 75% of operating costs. 1 kWh of electricity is equal to 4 kWh of electricity.

Environmentally friendly and pollution-free: There are no combustibles or emissions, making it a sustainable and environmentally friendly product.

◇ Safe and reliable operation: The entire system operates without the potential hazards of flammability, explosiveness, poisoning, short circuits, etc. that may exist in traditional dryers (fuel, gas, or electric heating), making it an absolutely safe and reliable semi enclosed drying system.

Long service life and low maintenance cost: It is developed on the basis of traditional air conditioning technology, with mature process technology, stable and reliable performance, and long service life; Safe and reliable operation, fully automatic without manual operation, intelligent control.

◇ Comfortable and convenient, with high degree of automation and intelligence: adopting automatic temperature control device, 24-hour continuous drying operation.

◇ Wide applicability, unaffected by climate: It can be widely used for heating and drying operations in industries such as food, chemical, pharmaceutical, paper products, leather, wood, and agricultural and sideline product processing.

5. Introduction to Control Panel

◇ Stable performance, easy operation, and can achieve multiple functions to meet different types of material drying methods.

Adopting PLc programmable control method, different drying curves can be set, such as temperature, humidity, etc., to be set as desired.

The heat pump in the heat pump drying device not only has the function of drying, but also has the functions of cooling and heating, realizing various functions such as low-temperature processing and greenhouse heating.

◇ Equipped with power-off memory function, one click setting, achieving intelligent management.